Turbocharger: what affects turbine life and leads to turbine failures

There is no assembly in a car more demanding to lubricate than a turbocharger (TKR). The turbine rotor, depending on the engine operating mode, may rotate at a speed tens or even hundreds of times higher than the crankshaft speed. To avoid semi-dry friction and accelerated wear of the rubbing parts, the oil must not only be supplied to the rotor bearings under high pressure, but also be of high quality.

In addition, the oil that goes into the cartridge, as the bearing housing is called, is also a coolant because the turbine gets very hot with the exhaust gases during operation. This means that the oil must be resistant to thermal stresses and retain its lubricating power for a long time. This is the second reason why, for turbocharged engines, whether old or new, liberties with the choice of maintenance oil are unforgivable. No matter how high the mileage, the oil requirements have not changed! What is specified in the instruction manual concerning the viscosity (SAE index) and performance characteristics (API and ACEA) of the oil pouring in, that must be taken into account when buying it, and saving on buying cheap, but not corresponding to the factory tolerances of the product will do the turbocharger a disservice.

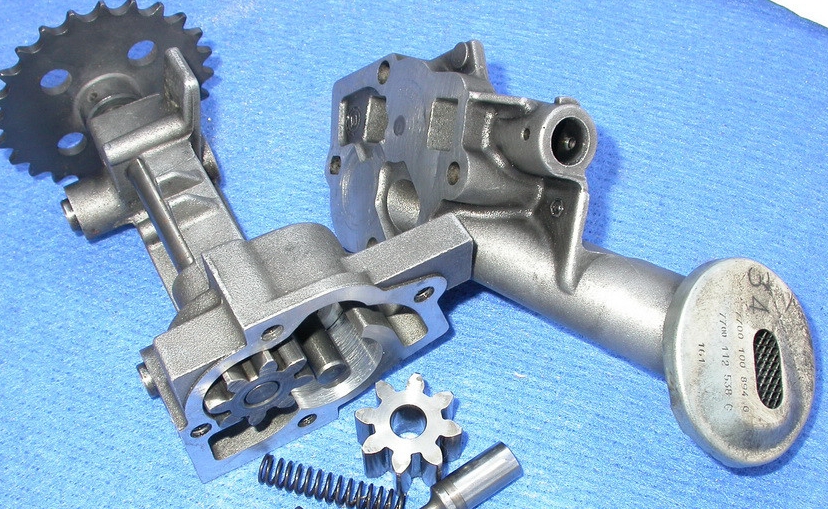

However, even if the oil is suitable, over time it accumulates wear products from all the friction points in the engine, as well as soot and carbon deposits. Dirt is trapped in the oil intake and oil filter. To be sure of the condition of the oil receiver, it is sometimes worth removing the oil pan. When the oil filter is clogged with debris, a special valve opens, which, to prevent oil starvation and semi-dry friction, lets the unclean oil flow straight to the turbine bearings. The same happens when the oil is too viscous. Until the engine warms up to a certain temperature, the oil is not filtered, but is routed past the filter through a bypass valve.

This situation requires that the oil filter and oil in turbocharged engines be changed at shorter intervals than for conventional engines. Replacement interval, according to many experts, should be no less than after 7-8 thousand km. Of course, the oil filter, as well as the oil, must be of high quality, not cheap, with dubious suitability for use.

Too viscous oil itself does not flow well to the cartridge, even if the filter is quite serviceable. To avoid delayed lubrication, oil starvation and semi-dry friction in the bearing assembly, the driver should refrain from sudden vehicle acceleration and forced driving until the engine is fully warmed up.

In high mileage engines, the oil pump, a malfunction in its actuator or even an oil intake screen clogged with sludge can cause starvation problems. Leaks can also contribute to oil starvation, for example, because the oil feed tube fitting on the cartridge is not tight enough. Also, the passage opening in the oil supply tube may be reduced because of fouling deposits inside or because the tube has been bent. The tube may be fine, but the strainer that may be in it is clogged with dirt.

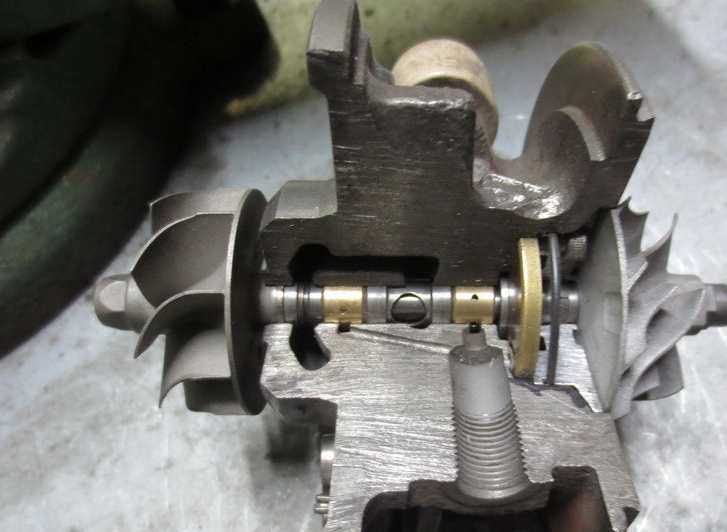

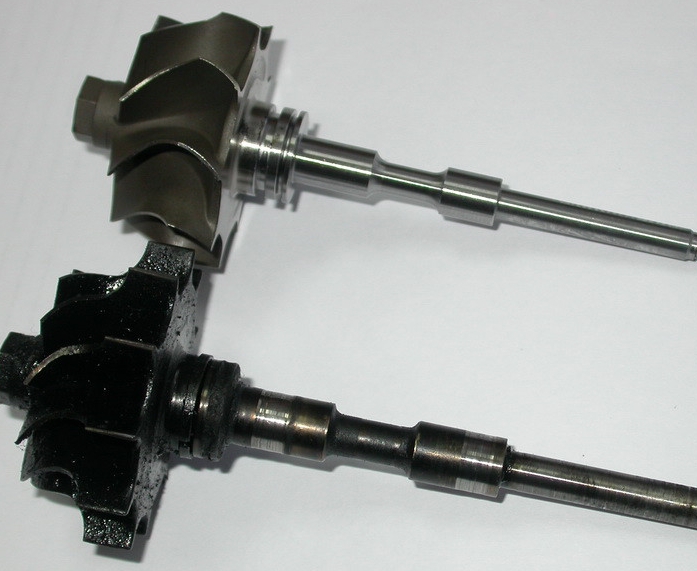

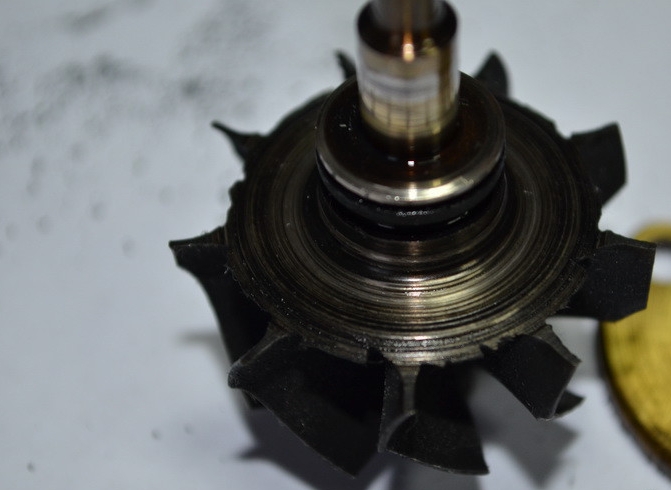

Theoretically, only the wear of the bearing bushes and the mating areas of the rotor shaft should govern the service life of a turbocharger. However, the practice of car service centers, specializing in the repair of turbochargers, shows that in far from isolated cases to the failure of the main unit of the turbocharger system leads to abrasive wear of the turbine wheel and compressor blades and even their mechanical deformation.

The turbine wheel can be damaged by something flying from the cylinders, such as pieces of valve seats. Fragments of broken air valves, which have been pulled into the cylinders from the intake manifold, can also reach the turbine. It happens that with the formation of fragments, the exhaust manifold cracks.

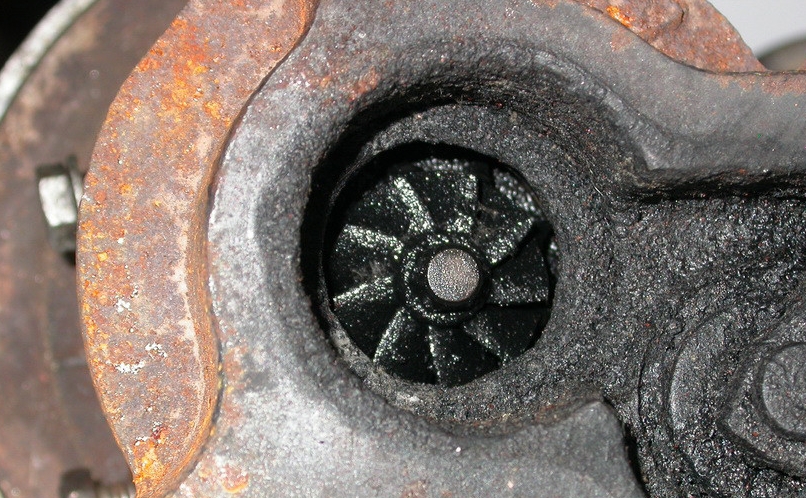

Finally, solid soot can form in the exhaust manifold, pieces of which then fall off and fly into the turbine. However, it takes some conditions to make the soot appear! Fuel combustion malfunctions contribute to the increased formation of soot that turns into carbon black. Causes can vary, from malfunctions in the power and ignition systems to the use of low-quality fuel. And high oil consumption due to the loss of oil, for example, due to wear of piston rings or valve scraper caps, again, does not bode well for the TKR.

Fouling has three other negative effects on the turbocharger. First, fouling causes the blades in the guide vanes of variable geometry turbines to jam and often lose mobility altogether, making them inoperable.

Secondly, the resulting fouling is deposited on the lips of the rotor seal. It is of the labyrinth type and consists of several metal rings. When the seal fails, the cartridge begins to leak, and the oil from it enters the turbine and compressor.

Third, the catalytic converter and particulate filter get clogged with soot. It would seem, so what? The problem is the emergence of significant resistance to free exhaust gases from the turbine.

When the obstruction appears, the gases begin to press on the turbine wheel, after which the thrust part of the wheel is intensively worn, and then the rotor has a longitudinal play, which should not be there.

This usually causes leaks, but it often gets to the point where the compressor wheel, which is on the opposite side of the rotor, shifts, starts to catch the blades on the body of its own “snail”, to be milled and even broken.

Other causes of damage to the compressor wheel vanes, as well as the guide vanes of the geometry change mechanism, are abrasive wear and foreign objects. These parts are worn by dust that has slipped past the air filter, such as through a loose clamp on an intake manifold or through cracks in the air filter housing or in the air duct between the filter and the TKR. This leads to a leakage of untreated air.

And the foreign objects are, as a rule, fragments of the air filter, which can split and rupture because of moisture, untimely replacement, as well as because of low quality of manufacturing. So the air filter should be treated with the same respect as the oil filter. And of course, you can’t ignore any whistling or other noise that occurs around the intake manifold. The sooner you find out its cause, the better. However, this applies to all engine problems affecting the TKR. To keep the turbocharger from dying prematurely, don’t delay in fixing them.

Other breakdowns are also possible, but they can hardly be called typical. In most cases, corrosion is the cause of such problems, but it takes a decent amount of time for it to cause damage to the actuator bodies or jamming of the actuator rods. And, of course, the TKR can be damaged in an accident.

Should the engine be shut down immediately after stopping the car? It won’t do any harm if it idles for a while. This will reduce the speed of the rotor, which has to rotate by inertia after stopping, which will reduce the time when its bearings will be left to starve the oil solder because the oil pump will stop working along with the engine.