The Fate of Sequential Turbocharging: Unveiling Its Journey

During the golden era of turbocharging, several automakers including Porsche, Mazda, Subaru, and Toyota embraced the concept of twin sequential turbos in their cars. However, as time passed, this technology has become scarce, with Bugatti being the only remaining brand that continues to utilize it.

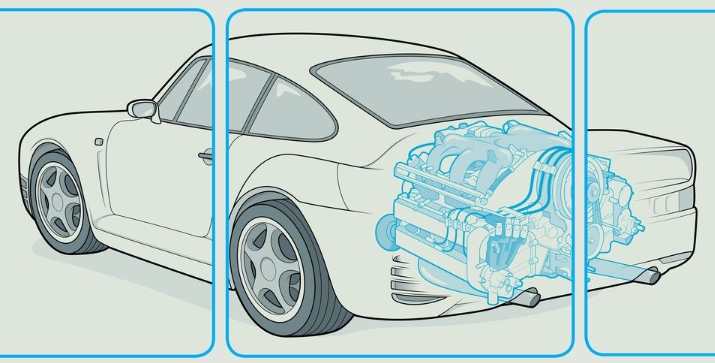

During one of the most remarkable and exhilarating moments of my career, I had the incredible opportunity to drive a Porsche 959. This extraordinary vehicle was graciously lent to me by the Porsche Museum, and its caretakers entrusted me with the keys for a thrilling drive along the roads surrounding Sonoma Raceway. What made this experience even more unique was the fact that I had the freedom to embark on this adventure without any supervision.

The entire experience was utterly surreal, largely due to the unparalleled driving dynamics of the Porsche 959. Powering this remarkable machine was a 2.85-liter flat-six engine, drawing inspiration from Porsche’s dominant 956 and 962 prototypes. Equipped with two turbochargers, the engine generated an impressive output of 450 horsepower and 370 lb-ft of torque (likely an underrated figure). What made the setup even more fascinating was the sequential operation of the turbos.

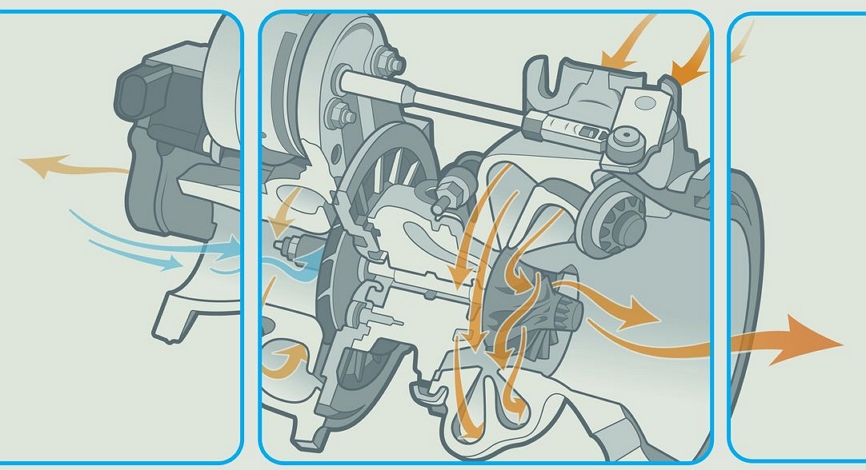

At engine speeds below 4000 rpm, the right-hand-side turbocharger was energized by exhaust gases from all six cylinders. However, once the engine surpassed the 4000 rpm mark, the exhaust gases from the left-hand cylinder were redirected to activate its corresponding turbocharger. This clever sequential turbocharging system allowed for optimal performance across the rev range, delivering a truly exhilarating driving experience.

In Paul Frere’s renowned book, “The Porsche 911 Story,” there is a fascinating explanation of the intricate plumbing system employed in the Porsche 959. However, for our purpose here, the key takeaway is that this system effectively minimized turbo lag. When the driver pushed the throttle to its maximum at 2500 RPM, the 959 would reach its peak boost of 14.2 psi within a mere two seconds. In contrast, a conventional parallel twin-turbo setup would require 6.5 seconds to achieve the same level of boost.

While driving the 959 around Sonoma, the experience was unlike anything else. Below 5000 rpm, it felt like a nimble and brisk vintage 911; but as the revs climbed, the acceleration was simply astonishing. The car exhibited an almost explosive surge of power as it approached its power peak at 6500 rpm. On that memorable day, a few of my colleagues also had the opportunity to drive the 959, and we all spoke in hushed tones about the awe-inspiring performance that unfolded when the second turbo came into action.

However, when Porsche introduced the 993-generation 911 Turbo, the successor to the 959, they opted to abandon the sequential turbocharging system. Surprisingly, Porsche never revisited this concept in their subsequent models, and only a few other automakers have explored it as well.

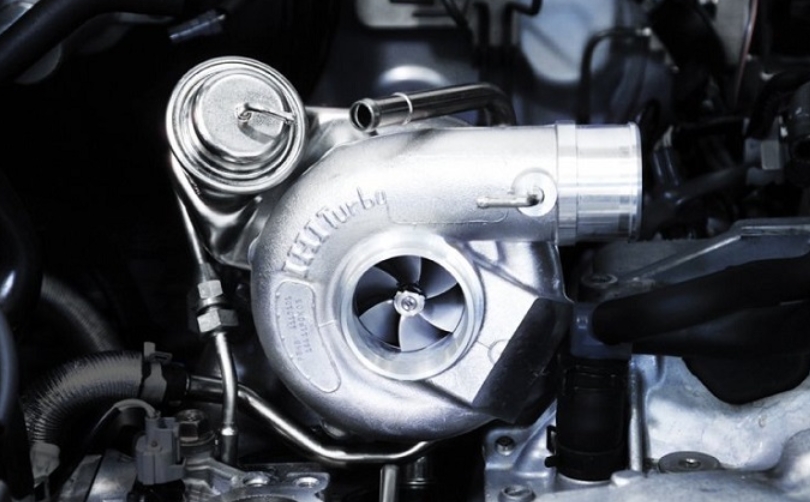

The underlying principle of a sequential turbocharging system is relatively straightforward. While a large turbocharger may provide the desired peak power, it takes a considerable amount of time for such a turbo to spool up, resulting in significant turbo lag. On the other hand, twin turbochargers operating in series, where one turbo feeds into the next, also encounter similar challenges. Two turbos operating in sequence, however, theoretically combine the benefits of a small single turbo’s quick spool-up with the capacity to deliver a substantial amount of air and horsepower at higher engine speeds. This configuration offers the potential for an ideal balance of low-end response and high-end performance.

The influence of the Porsche 959 was particularly noticeable among Japanese automakers. During the late 1980s, known as the bubble era in Japan, automakers had virtually unlimited budgets to pursue ambitious engineering projects. In an interesting anecdote, Nissan actually purchased a 959 to serve as a benchmark during the development of the R32-generation Skyline GT-R. While the GT-R didn’t directly adopt the 959’s sequential turbocharging, it drew significant inspiration from Porsche’s variable all-wheel drive system.

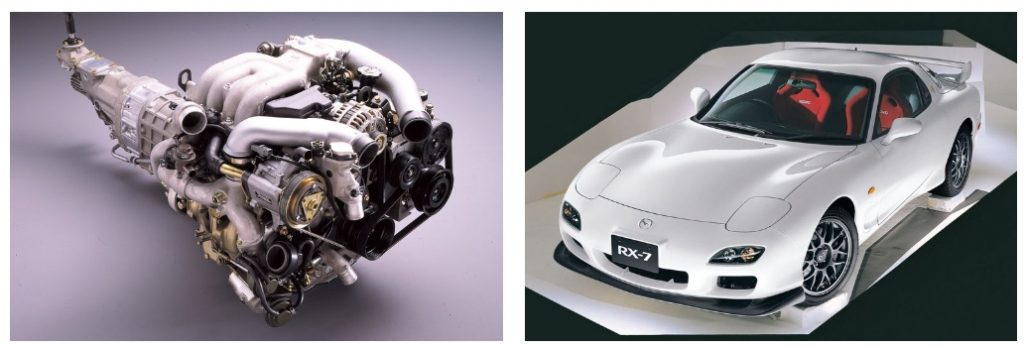

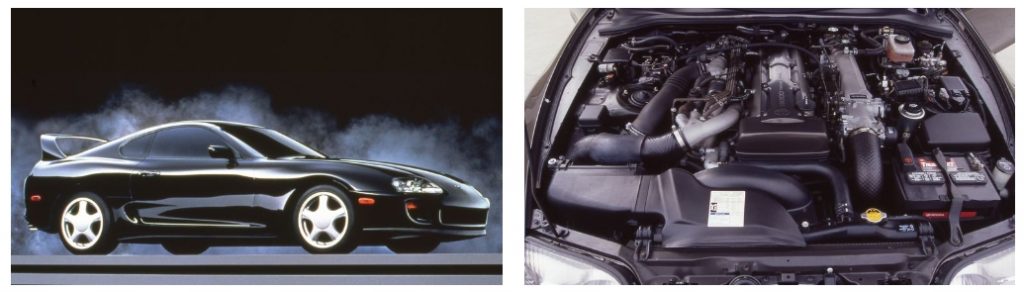

Mazda, on the other hand, embraced sequential turbocharging in the third-generation RX-7 and the three-rotor Eunos Cosmo. Subaru followed suit with various Legacy models, primarily those intended for the Japanese domestic market (JDM). However, the most iconic Japanese car featuring sequential turbos is undoubtedly the Toyota Supra, powered by the twin-turbo 2JZ-GTE engine. These systems employed a similar fundamental principle as the 959—exhaust gases were directed to one turbocharger at low RPMs, and then around 4000 rpm, a portion of those gases were redirected to a second turbocharger.

The question of whether sequential turbocharging is effective or not is a bit nuanced. During the time of their introduction, these setups represented a significant technological advancement, and they left a lasting impression. However, by today’s standards, cars equipped with sequential turbocharging can feel somewhat peculiar. While they are not excessively laggy, the transition when the second turbocharger kicks in is not entirely seamless. There’s a momentary pause in power delivery, akin to a flat-spot, and then suddenly, the car surges forward with remarkable force, almost as if it has been unleashed onto a race track.

However, the primary concern with sequential turbocharging lies elsewhere. Implementing this technology necessitates intricate plumbing and valve systems to effectively control the flow of exhaust gases. This complexity adds significant costs in terms of engineering and manufacturing, while also introducing a greater number of potential failure points. The development of the 959, for instance, incurred such substantial expenses that it nearly pushed Porsche to the brink. Similarly, for Japanese automakers that drew inspiration from the 959, the financial resources required to design and produce such intricate systems dwindled rapidly when the Japanese asset price bubble burst in 1992. This economic downturn occurred shortly after Mazda and Toyota had introduced their sequentially turbocharged cars, making it challenging for them to continue investing in such advanced and costly technologies.

Furthermore, the actual performance gains achieved through sequential turbocharging were debatable. While driving a 959 undeniably felt like a significant leap forward compared to earlier 911 Turbos, the introduction of the 993 Turbo with its simpler parallel turbocharging system—assigning one turbo to each engine bank—did not feel like a regression. In fact, according to Frere’s observations, the 993 Turbo exhibited impressive responsiveness thanks to the low inertia and small diameter of its turbine and compressor wheels. Frere noted that the 993 Turbo’s turbocharging setup provided a quicker response than that of the 959, although it is important to consider that the 993 Turbo’s 3.6-liter M64 engine boasted a 26 percent larger capacity, which undoubtedly contributed to its performance as well.

According to Steve Dinan, a BMW tuner and engine builder, the focus lies in maximizing power output while minimizing warranty claims and costs. He believes that the value of the technology used should be carefully evaluated, considering the incremental gains achieved versus the significant costs involved. While the existing technology may still be effective, the marginal improvements obtained are relatively small compared to the high expenses incurred, resulting in an unfavorable cost-benefit ratio.

When it comes to building high-power 2JZ engines, many opt to abandon the intricate sequential turbo plumbing and instead opt for either a single large turbo or two smaller turbos operating concurrently. Stephan Papadakis, a renowned engine builder, acknowledges that while it’s possible to engineer a twin sequential turbo setup to optimize performance at a specific power level, the complexities involved in terms of engineering and exhaust system design, including valve control and the need for turbochargers of slightly different sizes, make it far more straightforward to achieve comparable performance through simpler means. In other words, there are more straightforward approaches that can deliver performance on par with or even surpass that of a twin sequential turbo setup.

Papadakis Racing, known for its motorsports-prepped engines, chooses to utilize single turbos in their 2JZ builds. They prioritize simplicity and reliability over low-end response. While there are still instances where twin-turbo 2JZ engines are built, it is uncommon to find them with the sequential turbo setup maintained. Similarly, when tuning the twin-rotor RX-7, many opt to abandon the sequential turbo configuration for similar reasons, including concerns about reliability.

It’s important to acknowledge that turbocharging lost popularity in production cars towards the end of the 1990s. However, it experienced a significant resurgence in the 2010s as automakers recognized the advantages of downsized, turbocharged engines in meeting strict emissions and fuel economy regulations. During this period, advancements in both internal combustion engines and turbo technology rendered sequential turbocharging less appealing due to its inherent complexity. The use of lighter materials in turbine and compressor wheels allowed for quicker turbo spool-up, while sophisticated engine controls facilitated the generation of more low-end power. As a result, the necessity for large single or twin turbochargers diminished.

BMW briefly ventured into the realm of sequentially turbocharged diesel straight-six and V-8 engines, incorporating up to four turbochargers. However, it is likely that these experiments were discontinued due to similar concerns regarding cost and complexity. Nevertheless, automakers continue to explore new technologies aimed at reducing turbo lag and enhancing response in turbocharged engines. One popular solution is the implementation of twin-scroll turbochargers, which utilize specially designed exhaust manifolds to direct exhaust gases in pairs, maximizing energy transfer to the turbocharger and back to the engine. On the other hand, more advanced and less common are variable-vane turbochargers, which employ movable flaps to alter the shape of the turbine wheel, resulting in improved performance across a broader power range. While variable-vane turbochargers are primarily utilized in diesel engines, Porsche stands out as a notable advocate of this technology in gasoline engines.

A more recent advancement in turbocharging technology is the electric turbocharger, which integrates an electric motor into the common shaft connecting the turbine and compressor of the turbocharger. This electric assist enables almost instantaneous delivery of full boost pressure. Mercedes-AMG has embraced this technology in their new C43 and C63 models, while their 53-series straight-six models feature an electric auxiliary compressor. The electric auxiliary compressor operates similarly to a turbocharger but utilizes an electric motor to spin the compressor wheel instead of relying on exhaust gases. This electric auxiliary compressor can channel boost directly into the engine’s intake or assist the exhaust-gas turbocharger by pushing air through it.

Currently, there remains one automaker that employs sequential turbocharging: Bugatti. In the case of the Chiron’s W-16 engine, a straightforward valve system directs boost to one turbocharger per cylinder bank until reaching 3800 rpm. At this juncture, the valve opens, allowing the third and fourth turbochargers to engage. According to Bugatti test driver Andy Wallace, the primary turbochargers on each bank can achieve maximum boost, but as the engine revs increase, the 16-cylinder requires additional airflow, hence the involvement of more turbos.

The fact that the only car currently employing sequential turbocharging carries a price tag exceeding $3 million is significant. Even Bugatti, despite its prestigious status, is not exempt from increasingly stringent regulations, which will ultimately lead to the discontinuation of the W-16 engine. While it remains to be seen if Bugatti’s future production engines will continue to utilize sequential turbocharging, the trend for the majority of cars moving forward favors parallel operation of two or more turbochargers. In most cases, the simplest approach tends to be the most effective and practical solution.