The problems of modern turbochargers

Today, an increasing number of modern turbochargers are equipped with electronic boosters. Their main problem is that the lifetime of these units is often an order of magnitude shorter than the mechanical unit and if it fails it is almost always necessary to replace the turbine with a new one, which in itself is not cheap. The old principle of “the simpler, the more reliable” works in this case. For comparison we take the average service life of a turbocharger on a diesel engine with volume of 2000-4000cm3. with pneumatic valve supercharger control (it can be changed or repaired in extreme case) 200000-300000 km. run with normal operation and even more then service life of a turbine with electronic control unit is reduced in average 2 times. In addition they are more capricious to operate (they don’t like oil, dirt and fuel). In general, electronic units fail the electric motor, or teeth on gears are worn out. At first glance it looks like a small thing, but it is not solvable. If you are lucky you may find a second-hand unit, with no guarantee that it will work. The choice is not great!

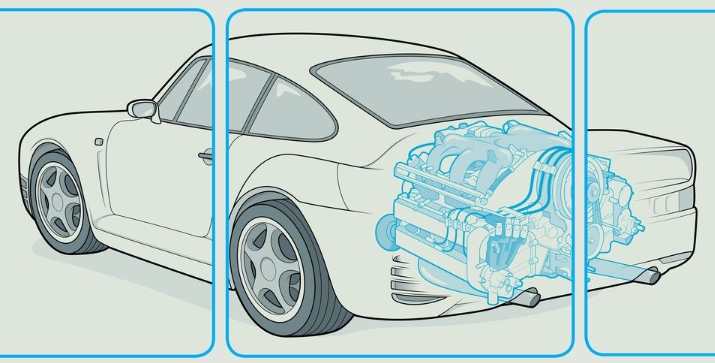

As for the pneumatic control valve, they are usually connected directly to the compressor part of the turbocharger and work to relieve excessive boost pressure (mostly found on turbines without variable geometry in the 90s.) Or through solenoid valves, which you can buy without problems for not much money.

When buying a car, think about how much it will cost to maintain it.